Authors: Nutsima Schnell Pictures used with permission of METTLER TOLEDO.

During the last ValidNMR meeting (March 7, 2019) the topic of the weighing process and the balances was discussed. In the past the focus was set more on the evaluation of the NMR spectra than on the sample preparation. As we all know, the sample collection and preparation setp is the most important part of the analysis. During the last years, besides GLP and GMP, the “Good Weighing Practice” (GWP) has becoming increasingly important. And who can better provide information about weighing than the balance producers? Thus, the ValidNMR community interviewed Nutsima Schnell, Klaus Fritsch and Tucker Rubino, three Mettler Toledo employees, who answered all our questions. Before we present the results of the Q&A we would like to a huge thank you to the Mettler Toledo employees sharing all the important information with us.

Let’s start with the Q&A!

How often should a balance be calibrated?

Calibration frequency depends on your risk.

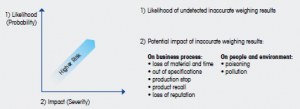

A starting position could be once a year. However, it’s important to consider the situation regarding quality, risks and the environmental impact on the actual application. There are various standards such as ISO 9001, ISO 17025 or ANSI/NCSL Z540 referring to equipment calibration. However, aside from the MIL-STD-45662A and ILAC-G24 / OIML D 10, none of them provides guidance on the subject of calibration intervals. We suggest therefore to rely on a risk-based methodology. For further explanations, please refer to the graphic below. The most effective method to care for and maintain your weighing devices is to schedule the following activities at intervals based on risk:

- Preventative maintenance (PM)

- Routine testing (RT)

- Calibration (CAL)

If a measurement is considered low risk then PM, RT and CAL can be carried out less frequently. Whereas, weighing devices performing high risk measurements will require more frequent PM, RT and CAL. Mettler-Toledo have set up a scientific risk-based weighing standard, GWP® (Good Weighing PracticeTM) that provides more information on that topic. Several literature was published around GWP, with a publication in NSCLI Measure as the most comprehensive paper (K. Fritsch, “GWP® – The Science-based Global Standard for Efficient Lifecycle Management of Weighing Instruments”, NCSLI Measure J. Meas. Sci., vol. 8, no. 3, p. 60-69, September 2013). For any particular situation, our METTLER TOLEDO GWP® Verification will help you determine a suitable frequency independent of your weighing instrument brand or model. For further information, please also refer to www.mt.com/gwp.

Can you mention why it is needed to perform “daily drift checks” on a balance?

There is no legal or regulatory requirement to perform daily drift checks. There was the habit for the last decades to perform a daily check on the balance, originating in the generation of mechanical balances where drift played a substantial role for balance errors. With electronic balances, drift is a minor issue, especially as most state-of-the-art balances are equipped with built-in weights to adjust any potential residual drift based on ageing, temperature variation and other external influences. FDA issued a statement many years ago that the frequency of balance checks shall be based on the risk of the application and can be partially replaced by the usage of the adjustment by means of the built-in weights, see www.fda.gov/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/ucm124777.htm. Other guidance documents as USP General Chapter 1251 “Weighing on an Analytical Balance” or UKAS LAB14 Ed. 5 “In-house Calibration and Use of Weighing Machines” also state that daily tests are not a requirement but tests shall be based on the risk of the application. See also GWP® for further guidance on that topic.

For routine testing, two calibrated weights are sufficient. The science-based global weighing standard, GWP®, states that testing at approximately 5% and 100% of balance capacity is sufficient. Start routine testing with the small weight, then use the large one. The small weight is used to carry out a repeatability test while the large weight is used to detect systematic deviations, e.g. sensitivity. Handling and maintaining two weights only simplifies routine testing and saves considerable purchasing and recalibration costs.

This approach applies to all balances in all industries. Our METTLER TOLEDO GWP® Verification will help you determine a suitable frequency independent of your weighing instrument brand or model.

Why not calibrating the microbalance around small weights (as required for qNMR sample preparation) to have small U at small weights?

One key objective of calibration is determining the measurement uncertainty associated with the error of a particular test point. However, calibration traditionally only reflects the situation at the moment of calibration and cannot be extrapolated to the uncertainty of the balance when used during day-to-day operation. State-of-the-art calibration guidelines, however, take the so-called “uncertainty in use” into account. The most widespread calibration guideline that extends to the uncertainty in use is EURAMET cg-18 “Calibration of Non-automatic weighing instruments” that was also transposed into a SIM guideline (“Sistema Interamericano de Metrología). Usually the uncertainty in use is provided as a function dependent on the mass, normally as a linear equation. In simple words, the measurement uncertainty in use increases linearly with the mass applied. Thus it is not required (and also not recommended by EURAMET cg-18) to have calibration points at the working points of the balance but have a rather equal distribution of the measurement points through the measurement range of the balance and then apply formulae to estimate the uncertainty in use. As a consequence, the uncertainty in use can be determined for any mass weighed on the balance during day-to-day usage. There are numerous publications on calibration and the uncertainty in use based on EURAMET cg-18, the most comprehensive one can be found in NCSLI Measure (K. Fritsch, I. Ciesniewski, “Calibration of Weighing Instruments: Measurement Uncertainty, Minimum Weight and the Safe Weighing Range”, NCSLI Measure J. Meas. Sci., vol. 10, no. 3, p. 56-65, September 2015).

Is the uncertainty in mass on a balance a random effect or the tolerance for a bias that would impact all weighings?

The uncertainty of balances) consists of random and systematic components. When weighing small samples or when weighing by difference, the most dominant contribution to measurement uncertainty is repeatability which is a random contribution to measurement uncertainty. Furthermore, rounding of a digital indication also may contribute significantly to the uncertainty when weighing small samples.

How accurate is a dosing unit (%)?

We believe that your question refers to an automated dosing unit. The accuracy depends on several factors, e.g. substance itself, target dose amount and type of balance used.

With our automated powder dosing system: we show an example of dosing Calcium Carbonate (Sigma-Aldrich 21061) as reference substance with Mettler Toledo system: XPR206DR and a powder dosing module Q2.

Tab. 1 Powder Dosing Specifications with Reference Substance Calcium Carbonate 1)

| Target amount (tolerance) | Dosing time* | Average powder dosed* | Dosing accuracy (rsd)* | Dosing time for 30 samples* |

| 1 mg (±20%) | 20 s | 0.974 mg | 4.21% | 21 min |

| 10 mg (±5%) | 22 s | 9.925 mg | 1.15% | 22 min |

| 50 mg (±1%) | 29 s | 50.069 mg | 0.26% | 23 min |

| 250 mg (±1%) | 38 s | 249.731 mg | 0.22% | 27 min |

| 1000 mg (±1%) | 71 s | 999.960 mg | 0.03% | 39 min |

1) Calcium Carbonate: Sigma-Aldrich 21061

* = data measured with an XPE206DR and a powder dosing module Q2

What is the minimum time you recommend to wait and consider for drifting weights in balance? Consider even in humidity controlled conditions as well.

Please refer to OIML R111 or ASTM E617 for weight acclimatization times. The equilibration times strongly depend on the nominal mass of the weights and the temperature difference between weights and environment.

Is mettler coming up.with humidity controlled balance enclosures?

Not at the moment.

How is mass accuracy impacted if weighing by difference. For example small mass recovered on syringe filter, mass measured before and after?

The differential method is used when a reference object, sample or substance is compared against a test object, sample or substance. If the reference mass and test mass are within 1% of each other’s nominal mass, the weighing instrument can be tested for repeatability only. The testing of linearity and sensitivity error is not necessarily required, as the samples compared are very similar in mass. Note however that the measurement uncertainty of differential weighing is a factor of square root of two higher as compared to simple weighing as two weighings are carried out, each contributing to the measurement uncertainty of the difference (uncertainties are added quadratically and can be considered similar for the two weighing operations as they are in the same weighing range of the balance, thus the uncertainty of a single weighing is taken quadratically two times).

How significant can electrostatic effects be during weighing procedures?

While hard to quantify, they can be very significant. Weighing errors arise through electrostatic forces that act between the weighing sample, vessel and the surroundings.

A typical indication of electrostatic effects can be: Each weighing shows a different result. The weight display is unstable. The repeatability of the weighing is poor.

Possible reasons: Your weighing vessel or the sample has become electrostatically charged. Materials with low electrical conductivity such as glass, plastics,powder or granulates cannot easily shed off these charges, oftentimes the charges dissipate over minutes or hours. Dry air with less than 40 % relative humidity increases the risk of this effect.

Corrective measures can be:

- Increase the atmospheric humidity: Electrostatic charging is particularly a problem in winter in heated rooms. In air conditioned rooms, setting the air conditioning to increase the humidity (45-60 % relative humidity) can help

- Screen electrostatic forces (Faraday effect): Place the weighing vessel in a metal container

- Use different weighing vessels: Plastic and glass charge quickly and are therefore unsuitable. Metal is a better material

- Use an antistatic kit: the compact METTLER TOLEDP anti-static kits or built-in modules are highly effective at removing static charges on the weighing vessel.!

Note: The balance, and hence the weighing pan, should always be grounded. All METTLER TOLEDO balances with three-pin power plugs are automatically grounded.

Some interesting references (including the link to mt.com for external access, can also be retrieved on picture park for internal purposes):

- https://www.mt.com/ch/it/home/library/guides/laboratory-weighing/laboratory_balance_and_scale_qa_guide.html

- https://www.mt.com/ch/en/home/library/guides/laboratory-weighing/weighing-the-right-way.html